High Voltage Electric Power Station Globe Valve

Products Design Features

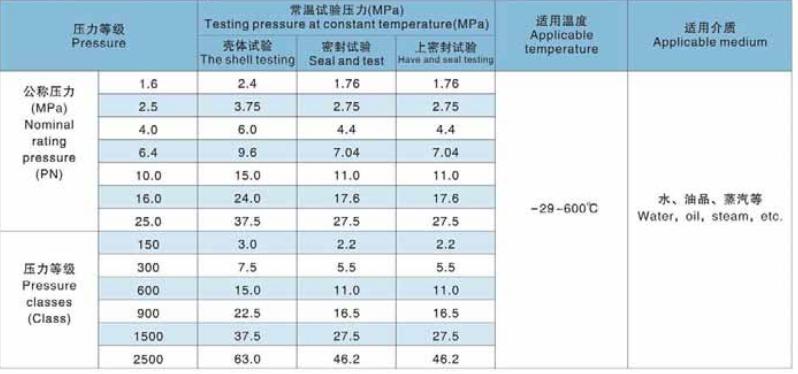

Globe valve are used to cut or connect the pipe media under nominal pressure betweenPN1.6-160MPa(Class150-2500) working temperaturess600C.in oil industry chemical industry pharmaceuticals fertilizer and power industry.

The main structure features include:

1. Rational structure.reliable sealing excellent performance pretty appearance

2. Co-radix alloy welded sealing surface anti-wearing erosion-proof abrasion-proof and longer use life.

3. The surface and the adjusting media of the valve shaft are nitrogenized so that it is erosion and abrasion resistant.

4. PN>25.0MPa(Class1500).the middle cavity use a self-tightening sealing structure to have the sealing performance reinforced

along with the pressure rise so as to ensure the sealing performance.

5. There is no backward sealing structure in the valve, so the sealing id reliable.

6. The material of the filling and the flange size can be chosen and matched according to the applications and the requirements of the use's. That can satisfies all kinds of working requirements.

The main structure features include:

| Serial models |

J11H、J11Y、J41H、J41Y、J541H、J541Y、J941H、J941Y J61H、J61Y、J561H、J561Y J961H J961Y |

||

| Pressure grade range | PN1.6-42.0MPa(Cass150-2500) | ||

| Drift diameter range | DN15~400mm(NP81/2-NPS16) | ||

| Driving manner | Hand wheel driving | Gear driving and electric driving | |

|

Scope of application |

Class150-300(PN1.6-2.5) | Class400-900(PN6.4~16.0) |

NPS/2~NPS16(DN15-400mm) |

| NPS1/2-NPS12(DN15-300mm) | NPS1/2-NPS16(DN15-400mm) | ||

Products Performance Specification

Technical Specification

| Structural formation | PS - GB - OS&Y |

| Driving manner | Hand-operated, Gear-operated and Electric - driving |

| Design standard | ASME B 16.34 BS 1873 |

| Face to face | ASME B 16.10 |

| Flanged ends | ASME B 16.5 |

| Butt-welding ends | ASME B 16.25 |

| Test & inspection | API 598 BS6755 |

Note: The sizes of valve connecting flange and butt-welding terminas can be designed according to customer's requirement.

Major Parts Material Form

| No. | Part name | Material |

| 1 | Body |

ASTM A216-WCB ASTMA217-WC1WC6WC9.C5 ASTMA351-CF8CF8MCF8CCF3CF3M |

| 2 | Disc |

ASTM A182 F6aASTMA182F22.F11 ASTM A182-F304、F316F321、F304LF316L |

| 3 | Stem |

ASTMA182 F6aASTMA182F22F11 ASTMA182-F304 F316 F321 F304L、F316L |

| 4 | Flat cover |

ASTM A182 F6a、ASTMA182F22 F11 ASTM A182-F304、F316、F321、F304L、F316L |

| 5 | Bonnet |

ASTM A182 F6a、ASTMA182F22F11 ASTMA182-F304F316 F321F304L、F316L |

| 6 | Gasket | Graphite & stainless steel |

| 7 | Yoke |

ASTM A216-WCB ASTMA217-WC1 WC6WCCS ASTMA351-CFBCFMCF8CCF3CF3M |

| 8 | Stud | ASTMA193-B7A193-B8、A193-B8M、B16 |

| 9 | Six angle nuts | ASTMA194-2HA194-8A194-8M7 |

| 10 | Packing | Graphite |

| 11 | Packing gland | ASTMA216-WCBASTMA217WCWCWCC5 ASTMA351-CF8CF8MCF8CCF3CF3M |

| 12 | Valve stem nut | Copper alloy |

| 13 | Driving | Hand-operated, Gear-operated and Electric - driving |